Questions and answers about LCN:

In text form, as video tutorials and in LCN webinars.

- All

- Installation

- Operation

- Top

- General

General questions

Or by hotline: +49 (0) 5066 998 855.

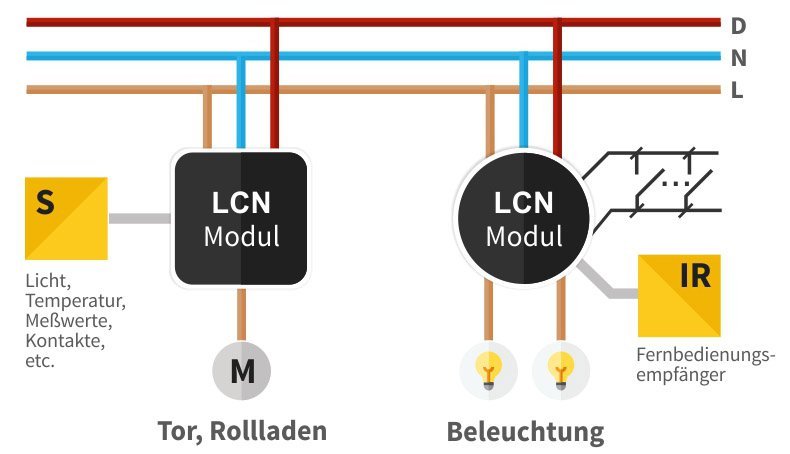

Mit dem Local Control Network können alle Funktionen eines Gebäudes automatisiert werden. The modularly expandable LCN system makes it possible to link manual commands with automatic functions.

- Energy saving through temperature control

- Control interior lighting depending on exterior light

- Save and recall light scenes

- Solar control system: automatically control blinds/shutters, etc.

- Execute controls time-dependently

- Time recording system, access control

- room control

- Process and display alarm messages according to DIN

- Operation via phone or tablet

- and much more

LCN is particularly easy to install, as it does not require its own cable network. Only one free wire in the existing house installation. The parameterization is very simple, even an employee who only occasionally uses the bus technology would be able to handle it. And because the software helps in many places, even with troubleshooting, LCN saves time and money on the job site. The system can be easily read out at the push of a button.

Electrical equipment may only be installed by qualified electricians. That is why we work exclusively with qualified and certified partners nationwide.

Products from LCN can only be purchased from our technical partners via our online store and electrical wholesalers.

Yes, the system can be accessed and controlled from the outside by means of an access from the Internet. We offer you various options and apps for this purpose.

Q&A Installation

LCN is easy to install, insensitive to external interference and realizes a lot of functionality with only a few modules. LCN can control all sizes of buildings, from single-family homes to high-rise office buildings.

A smallest conceivable LCN installation would consist of a bus module, for example an LCN-UPP, and an operating option such as an IR receiver or a glass keypad. The bus module is connected to the usual house installation, consumers such as lamps or motors to the bus module, as well as the operating system. One wire of the house installation serves as a data wire for communication between the modules.

A coupling module LCN-PKU is additionally, mostly temporarily, connected to the LCN bus. A PC with the LCN-PRO software then allows the system to be parameterized, i.e. which actions are performed in which situations and how. The LCN Starter Set LCN-SKO contains more than just the most necessary parts of a first LCN system and thus allows a quick and uncomplicated introduction to LCN.

The LCN bus can extend up to 1000 meters. Up to 250 modules can be connected to it. Because, in addition, sensors, glass pushbuttons or relay blocks are connected to many modules, the actual number of data points and consumers is much higher. For a particularly compact installation, an LCN-R6H relay block can be plugged into the LCN-SH DIN rail module, for example. This results in eight outputs and additionally the possibility to connect eight keys – to only one bus participant. If longer distances or more modules are required, the bus can be split into segments, which are connected via segment couplers (see next point). With connections via fiber optics, networks of up to 30 kilometers are possible.

For example, an installation in a private building may consist of only a few modules, together with a few sensors and pushbuttons. Or 30,000 modules in complex large buildings with more than 500,000 data points. The distance between modules can be a few centimeters, or up to several hundred meters – without the need for couplers or repeaters.Using fiber optics, the LCN bus can be extended up to 30 kilometers. In addition to thousands of residential buildings, the Maintower in Frankfurt am Main, one of the largest buildings in Germany, has been successfully implemented with LCN.

Unlike other automation systems, LCN does not require special wiring. A standard NYM cable is laid with an additional core, for example 4 x 1.5 mm². In practice, five-core cables are used because they are commercially standard. One wire remains free for other tasks. An extra line network is not required for the LCN bus. The data wire is treated as a mains wire and may therefore be routed together with the 230 V installation in accordance with VDE. The LCN modules do not require additional power supplies. They are connected directly to the mains voltage.

- Low number of modules thanks to combination of sensor and actuator, thus cost-effective.

- Few planning rules to follow.

- Clearly arranged bus topology.

- Easy to maintain by electrician, no expensive specialist required.

- Use of conventional pushbuttons, motion detectors, etc.

- Expandable over 60,000 sensors and actuators.

- Very powerful: no data loss in large installations.

- Real feedback included as standard.

- In a very wide range price adaptable to the wishes of the builder.

- Very high “intelligence” and functionality.

- LCN is the world leader in terms of transmission performance of installation buses.

- LCN offers an unmatched number of functions per module. Thanks to this diversity, LCN flexibly adapts to the building and the demands of the building owner.

- LCN is the only system to have a four-level acknowledgement and reporting system, enabling very high quality installations with comprehensive building monitoring

- Thanks to higher integration, LCN is less expensive than other systems and lowers the entry threshold for installation.

- LCN is unbeatable in ease of installation and programming. This helps the specialist engineer and the installer. And it helps the building owner: His contact person remains his installer “around the corner” and not an expensive specialist.

LCN is an open system and integrates into existing infrastructures. As an open bus, LCN allows problem-free coupling to almost all interfaces such as BACnet®, Modbus®, OPC, BMA Bosch, IOS, IP-Symcom® or EnOcean® via various interfaces.

Three training courses are offered for LCN: a basic course for the important entry-level knowledge, an advanced course with more details and complex topics, and a course for the LCN-GVS visualization. In addition, courses for teachers or wholesalers are still offered. Find out more on our training page.

ISSENDORFF KG offers two hotlines as support for the LCN system. A technical hotline is available by telephone throughout the day to answer questions about commissioning, technical design, troubleshooting and parameterization. The only requirement is that you have participated in an LCN training course or have purchased an LCN starter kit. The planning hotline provides support with planning and costing as well as with information on LCN sources in your area.

The LCN Local Control Network operates at a very high transmission speed, even though it is based on conventional cabling. If a very large number of modules is used, the bus can be divided into segments so that communication in the entire system is also reduced to the areas that exchange messages most frequently. With 1,000 to 10,000 telegrams in the upper bus level and 100 telegrams in the lower bus level, LCN’s transmission performance puts it at the top in a worldwide comparison of installation buses.

Q&A LCN-SKO

The telegram counter in the LCN-PRO counts the telegrams continuously and the adjacent bar is green and shows the text message “Online”.

At rest, the two green LEDs are lit. During bus traffic, the red LEDs flicker. If the red LEDs are continuously lit or if only one green LED is lit, the bus is faulty. (see also LCN-PKU/LCN-VISU installation instructions)

Tip:

If the LEDs of the LCN-PKU/VISU indicate phase on the data wire, switch off one circuit after the other until the red LEDs go out: The wiring error is to be found in this circuit.

LCN bus modules are connected to the data wire. Their own intelligence allows bus communication, as well as the management of connected peripherals. Bus modules are LCN-UPP, LCN-UPS, LCN-UPU,LCN-UMR, LCN-SH, LCN-SHS, LCN-SHU and LCN-HU. The connected periphery does not have its own intelligence and therefore always requires an LCN bus module. It is connected to the T-, I- or P-port.

In general, all components that you do not find under the corresponding menu item. These are for example:

LCN-GT4D, LCN-GT10D, LCN-GBL, LCN-TS, LCN-B3I, LCN-BT4H, LCN-BU4L and LCN-PMI on the I-connector.

Right-click on the segment and select “Find more modules”. The LCN-PRO now searches for unprogrammed and programmed modules. If unprogrammed modules were found, the modules appear with the corresponding serial number and hardware type (icon).

Each LCN product comes with an installation manual that contains all the necessary information. We recommend that you read these instructions carefully before commissioning.

IDs 5 to 254 are available to you – a total of 250 IDs per segment. ID 1-4 are reserved, e.g. for LCN-PRO (ID 1). Note: You should not use the maximum possible number of 250 modules (IDs) per segment! In case of an extension of the system, no more free IDs would be available!

Click with the left mouse button on the unprogrammed module and assign it an ID.

You can give the module a name (max. 20 characters) and a comment (max. 36 characters). The name describes the location and possibly the connected hardware, e.g. “GF LIV RM Door TS B3I BMI”. Recommendation:

lways name the modules according to a uniform scheme, e.g.: “ggg rrr zzz” where ggg = floor, rrr = room and zzz = additional info. The comment indicates which consumer is controlled, e.g. “A1 L Ceiling A2 L Wall”. In case of later changes, you can easily and quickly find the affected modules again.

With this setting you can switch the triacs in phase zero crossing and dim them in phase angle. In addition, the corresponding values are output on the ECG interface.

For dimming values above 1%, the outputs are immediately switched to 100%. The dimming values are now only output via the ECG interface as a 0-10V or DALI signal.

Check whether the outputs of the modules are activated, e.g. “Standard (dimming, switching…)

In symmetrical pulse-packet control (oscillation-packet control or multi-period control), current passage through the triac is enabled (fired) during a number of whole oscillations and disabled (not fired) during a number of subsequent whole oscillations. The cycle duration is adjusted. The shortest cycle duration is 5s and the longest is 645s. The dimming value defines the ON/OFF times.

Example:

Cycle duration = 60s

Dimming value Outp. 1 = 20%

Output 1 is switched ON for 12s and switched OFF for 48s

Each LCN remote control can address 16 buttons. In the case of the small LCN-RT, this is achieved by switching over (see LCN-RT installation instructions: Key levels). With the selection “Affects: Table A/B”, eight keys of the A table, and another eight keys of the B table are reached. The four membrane keys of the LCN-RT trigger keys A1 to A4 directly (key level 0) – ideal for the first attempts. The remote control therefore operates the same buttons as connected pushbuttons. If you select “Works on: Table B/C”, the remote control will operate on the B and C button tables. This selection would have to be chosen if the connected LCN-GT8 pushbutton is to have other functions than the remote control.

Q&A LCN-PRO Parameterization

The LCN system is parameterized with the Windows program LCN-PRO. This defines how modules or parts of the LCN system act with the environment, which commands and functions are expected. In addition, the functions of control elements such as glass keypads are defined.

LCN-PRO allows parameterization of all functions of an LCN system. LCN-PRO can be used either in offline mode to lay out an LCN system before the actual installation, or in online mode also via the Internet, where all changes are immediately entered into the modules. LCN-PRO is extremely compact and very efficient. LCN-PRO processes all LCN modules from 1996 onwards and automatically offers the possible functions.

A Microsoft® Windows® PC with at least four MBytes of memory and a few megabytes of free hard disk space is required. At least one free USB 2.0 slot is required for coupling to the LCN system via the LCN-PKU coupler. LCN-PRO does not use external DLLs, does not affect foreign directories and does not make any entries in the registry. All operating system versions from Windows 7 are supported.

No, LCN-PRO is a paid product. You can obtain a license of LCN-PRO in the webshop or with the LCN-SKO training case.

LCN-PRO does not require programming skills or knowledge of programming languages. Only knowledge of the general operation of Windows programs is expected. Nevertheless, a basic knowledge of the LCN system is necessary, which is best acquired in an LCN basic course.

In the parameterization in LCN-PRO, it is defined in the modules which functions are executed in case of certain events, what external events from operating systems or sensors should cause and in which way these commands are executed. For example, it is possible to define to which brightness lamps are controlled and which dimming operations are performed. For this purpose bus modules have control components, they can execute arithmetic and logic functions, read values from other modules or send commands to external modules. All in all, LCN-PRO has a very extensive functionality, but its clear user interface makes it easy to use even by beginners in the LCN system. Gradually, deeper and more complex functions are then worked out. The optional grouping of components of the LCN system such as lamps or entire modules into groups simplifies parameterization.

Unlike other systems, the entire parameterization is stored in the LCN system itself. Even plain text identifiers of modules or inputs and outputs are transferred to the LCN system. Therefore, if the source file of an LCN installation has been lost, the entire parameterization can be read back from the LCN installation, even after many years.

LCN-PRO is used for parameterization of an LCN system, i.e. assignment of functions and behavior. LCN-GVS is the Global Visualization for LCN. LCN-GVS is used to form a graphically-oriented user interface for one or more LCN systems, where the user interface can be any web browser on any type of system. Therefore, the GVS of an LCN installation can be reached worldwide via the Internet, of course encrypted and thus protected. For this purpose, LCN-GVS stores biometric and general data for access control practically without limits, offers timers in the system and many other functions to operate an LCN installation conveniently and highly automated. A freely available app for iOS® and Android® optimizes data traffic and display for the LCN-GVS for mobile systems.

LCN trainings

In just two days you will go from beginner to professional. This will make your first project much easier to handle and you can use the free service of the LCN hotline. LCN training courses are offered throughout Germany at chambers of trade and guilds. We offer the following courses in our house:

LCN-SKO

Sample and training case-

Training case of the LCN bus system

-

extensive LCN basic equipment

-

full software license LCN-PRO

LCN professional courses

LCN Basics for Professionals-

Basics LCN installation

-

Basics parameterization

-

extended LCN functions

Visualization course

LCN-GVS Visualization-

Structure of the GVS visualization system

-

Design of the user interface

-

Setting up the functions

We are here for you

We support you during commissioning, technical execution, troubleshooting and parameterisation.

Give us a call!